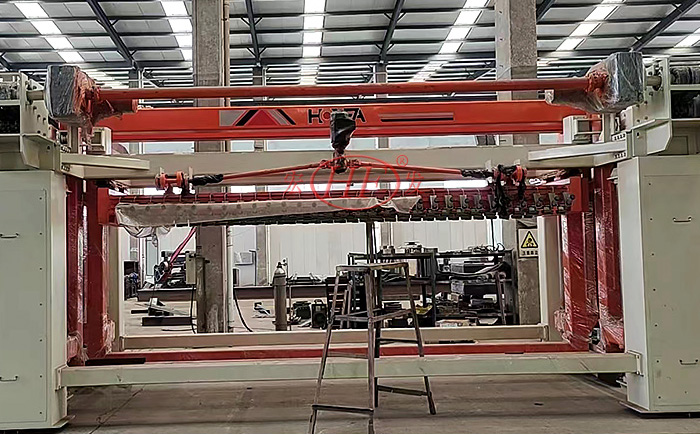

Aerated block cutting machine

一、 Introduction to air block cutting machine

As the main equipment in the process of aerated concrete production, the quality and cutting precision of the aerated block cutting machine directly affect the quality of the aerated block. Our company's JQF series flips air block cutting machine, with high efficiency, high degree of automation characteristics.

二、Air block cutting machine main features:

1. The model structure is simple and practical, easy to install and maintain;

2. After the body is turned upright, the body width is 600mm and the height is 1200mm, so the cutting steel wire is shorter, so it is not easy to break, not easy to drift, and the cutting precision is high;

3. The longitudinal cutting device is walking (the body is fixed on the cutting table) to complete the longitudinal cutting. Horizontal crosscutting device adopts screw drive to keep the same lifting drive of crosscutting frame and ensure cutting accuracy;

4. The body walks, the air block cutting unit is fixed, and different cutting functions are completed through different equipment positions, so the corresponding notch processing or vacuum adsorption unit can also be assisted;

5. In addition to the production of blocks, this model can also produce plates, and the billet is cut on six sides, so the quality of the product is not affected by mold oil and mold deformation.

6. The cutting and turning table can be configured to turn over the blank after the cutting is completed, which is convenient to remove the waste on the bottom surface, and then turn back to the initial state.

7. Highly intelligent operation and management, using PLC centralized control, with frequency converter to achieve the entire cutting process automatic operation.

8. The operation of the equipment is simple and convenient, the cutting process (flipping, longitudinal cutting, transverse cutting) is completed in different stations, and the cutting and walking control are in different devices, because some work is simplified and the operation and maintenance are convenient.

三、Air block cutting machine working principle:

After the overturning hanger turns the mold over 90 degrees in the air, the blank body and the mold side plate are placed on the cutting table. The longitudinal cutting device drives itself by the motor to walk and cut the blank body placed on the cutting table. After the cutting is completed, it walks to the pause position. The transverse cutting frame is cut vertically from top to bottom until it rises and resets.

四、Air block cutting machine working mode:

(1) Car walking: the pre-conditioned body with the mold is turned 90 degrees in the air, and then the body is placed on the cutting machine, and the mold frame is removed by the stripping mechanism. Then the horizontal cutting car performs horizontal cutting, after the horizontal cutting is good, the transverse cutting car is positioned vertically from top to bottom, and the transverse cutting car is reset after the cutting is good, the billet is lifted, and the horizontal cutting car is restored.

(2) Body walking: the pre-conditioned body with the mold is turned 90 degrees

in the air, and then the body is placed on the cutting car or the roller table, and the mold frame is removed by the stripping mechanism. The blank body is cut horizontally by the car or the roller table. After cutting, the blank body continues to move to the cross-cutting position for positioning and transverse cutting. After cutting,

the blank body is lifted by the truck.