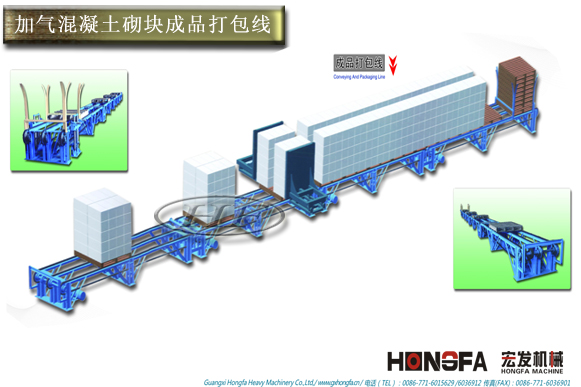

Filling block packing line

The packing line of aerated concrete block is mainly composed of baling machine, chain conveyor, plate feeder, billet combining machine, etc.

The main function of the chain conveyor is to transfer the finished product packaging of the air block, and its specifications and sizes can be customized according to the actual needs of users.

The main function of the plate conveyor is to realize the automatic transmission of the pallet when packaging, which can save a lot of manpower, save costs for customer production, improve efficiency, and the specifications and sizes can be customized production;

The billet combining machine is mainly used for the billet combining in the packing section of the finished product from the kettle.

Below we focus on the air block through the sword baler:

Air brick baler is designed for the packaging of air brick with pallet, open bow frame, movable belt can firmly pack the pallet and packaging together, easy to move and transport.

1. The sword motor starts the gas block packing line after the stack of the gas brick packing production line is in place to complete the sword body threading, and the movement moving cylinder starts after the conveyor is in place. The moving movement is detected by the induction switch and attached to the surface of the stack switch body, and the movement motor runs to complete the binding. The equipment adopts PLC control, which is stable and reliable, and has the function of belt position detection, sword body in place, movement in place and so on.

2. Packing operation sequence of air filling block packing production line:

According to the requirements of customers and the packing line of air block brick on site, as well as the size of the assembly line, the unmanned automatic piercing arrow baler is designed to meet the requirements of customers.

Packing sequence: The packaged object is transported to the special equipment of the air block packing line in the packing range of the baler through the conveying line. After being positioned by photoelectric induction, the baler automatically enters the packing state;

The first step, the whole gas brick packing production line is driven by the power motor, and it moves forward to fit the package. The fitting surface is equipped with an induction switch in place. When the switch touches the object, the baler stops moving forward;

The second step, driven by the power motor, will automatically pass the packing belt sword slot into the pallet hole of the packaging object, reach the opposite bow frame and stop;

The third step is the packing line of the aeration block after the flip kettle. After the above action is completed, the packing belt automatically enters the bow frame, and the packing belt is confirmed by the detection switch in place.

The fourth step, after the end of packaging, the sword slot automatically returns to the baler, the whole machine returns to the original position, the packaging continues to be transported and so on to complete the packaging times required by the customer. All the detection functions in place are completed by photoelectric reflector induction, travel switch and induction switch.