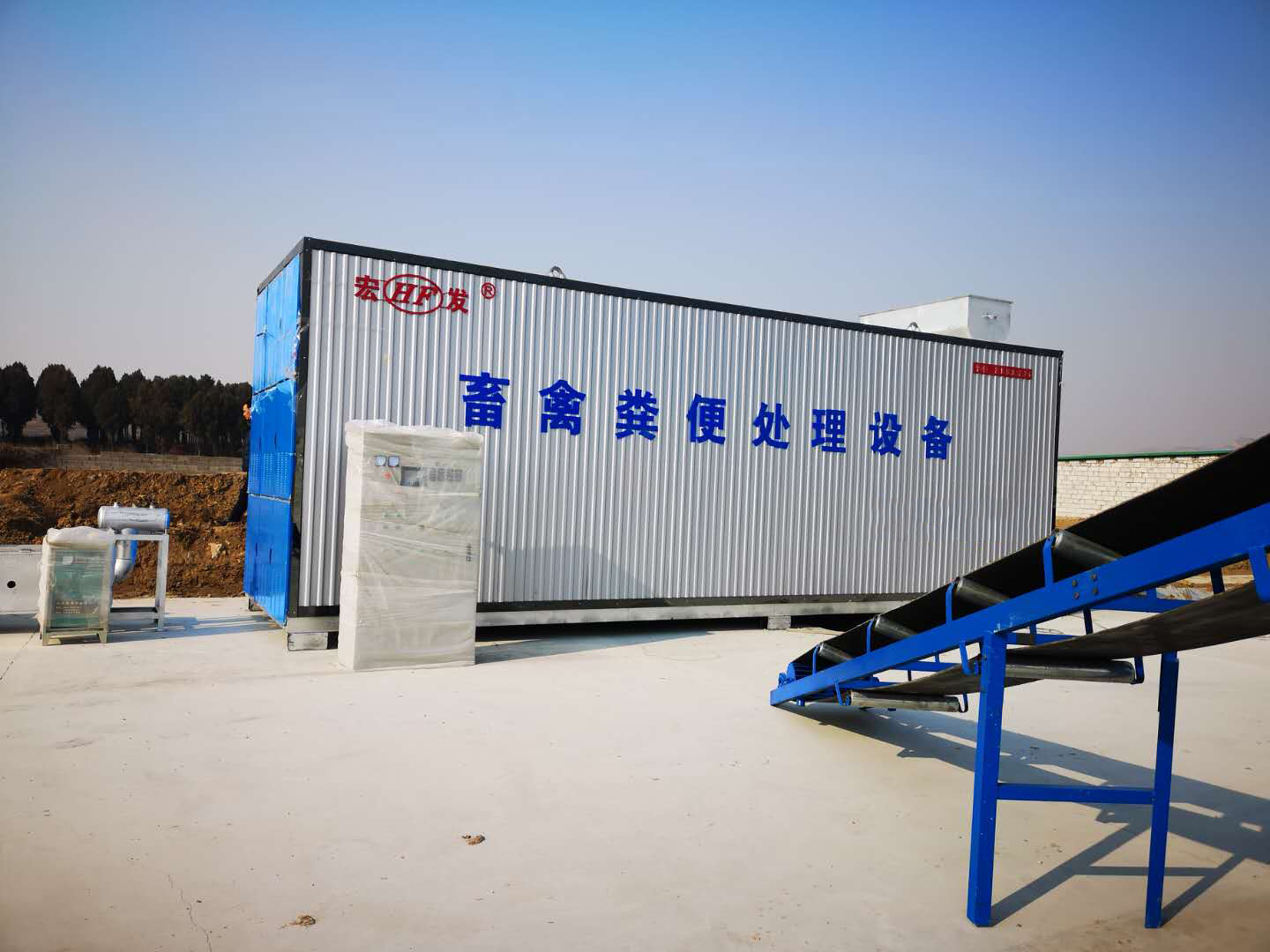

Livestock manure, agricultural straw comprehensive treatment equipment

Livestock and poultry disease and death harmless treatment equipment:

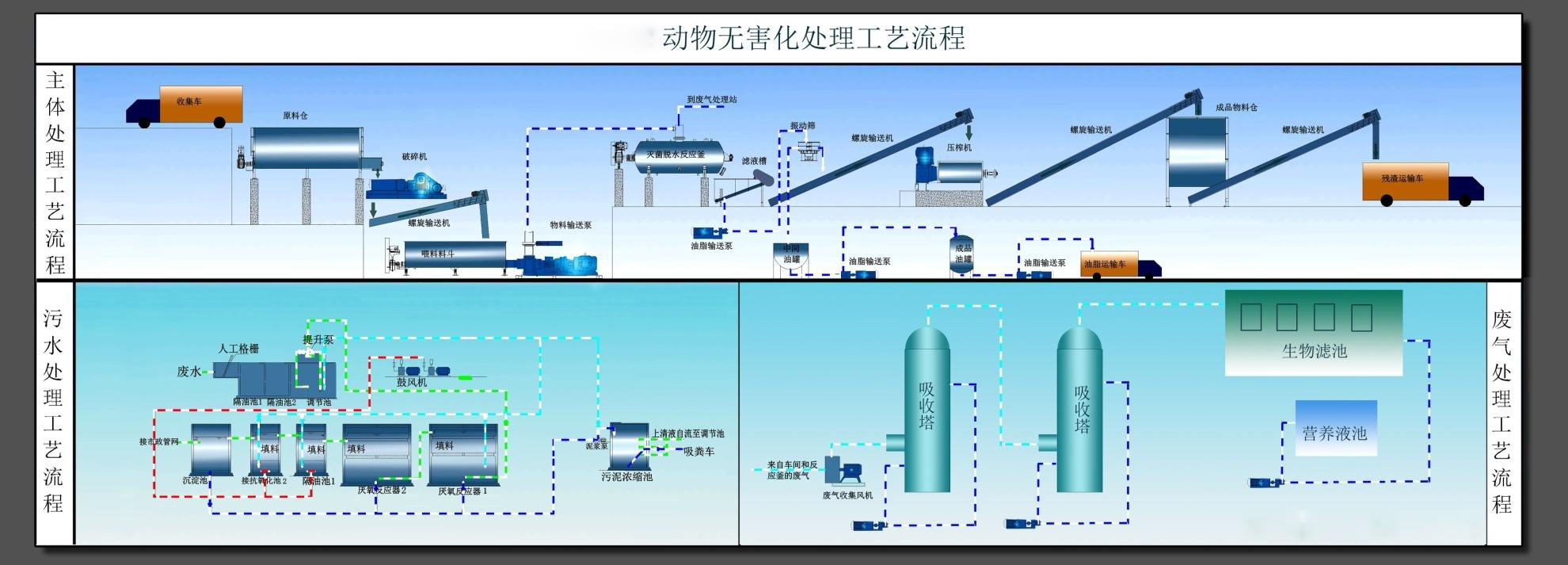

It refers to the technology of transporting dead animals to a closed container after crushing treatment, and at the same time, introducing high temperature circulating heat source into the interlayer for high temperature and high pressure treatment of dead animals and poultry carcass. During the treatment process, the heat source does not directly contact the dead animals' carcass, and uses the water inside the animal to heat and vaporize to generate pressure. Through vacuum drying, degreasing, cooling, crushing and other processes, meat and bone meal and industrial oil are obtained. Hongfa livestock and poultry harmless environmental protection equipment adopts dry harmless treatment method, which has the functions of fast processing speed, no secondary pollution, high automation, low labor intensity, high purity of finished products, environmental protection process, etc. It is an alternative to fermentation treatment and humidification treatment.

【 Hongfa Heavy Industry 】 Harmless treatment process of livestock and poultry:

1, the collection of dead livestock and poultry: dead animals by the collection of the township animal epidemic prevention station to assist the completion of each township according to the region and the amount of breeding to build one to two collection points, the annual volume of more than 50,000 livestock farm construction collection cold storage, farmers will be dead animal carcasses transported to the township collection point, processing center collection car once a day to the township collection point to collect animal carcasses.

2, material storage: Transport vehicles to the processing plant, should be collected with the processing, can not be timely treatment of sick and dead animals, put into the cold storage or temporary storage area, waiting for processing. After unloading the vehicle, the vehicle should be disinfected and cleaned with a disinfection washer.

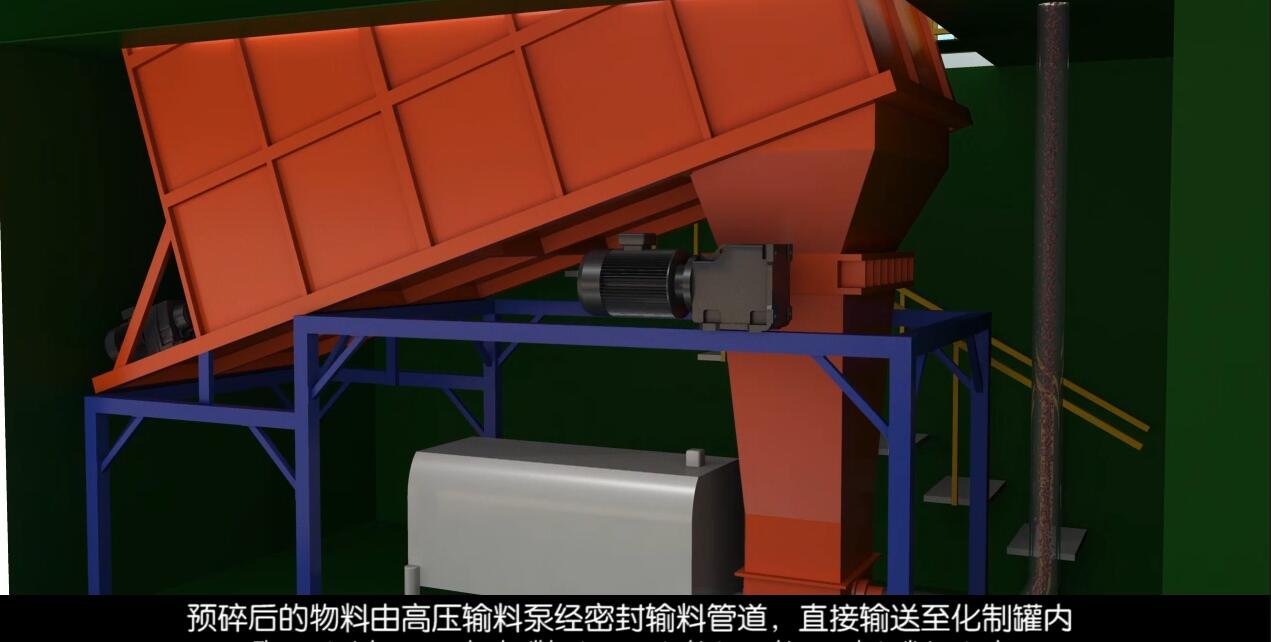

3. Crushing treatment: The dump truck will pour the sick and dead livestock into the closed storage bin, and the material will be transported into the pre-crusher through the screw conveying equipment, and the material will be broken into meat pieces with a diameter of about 50mm in a closed environment.

4. Material transportation: The broken material is transported to the chemical tank by the feed pump through the closed pipeline, and the whole process is closed and automated. The feeding method has many advantages such as fast speed, small residue, easy cleaning and no foul odor.

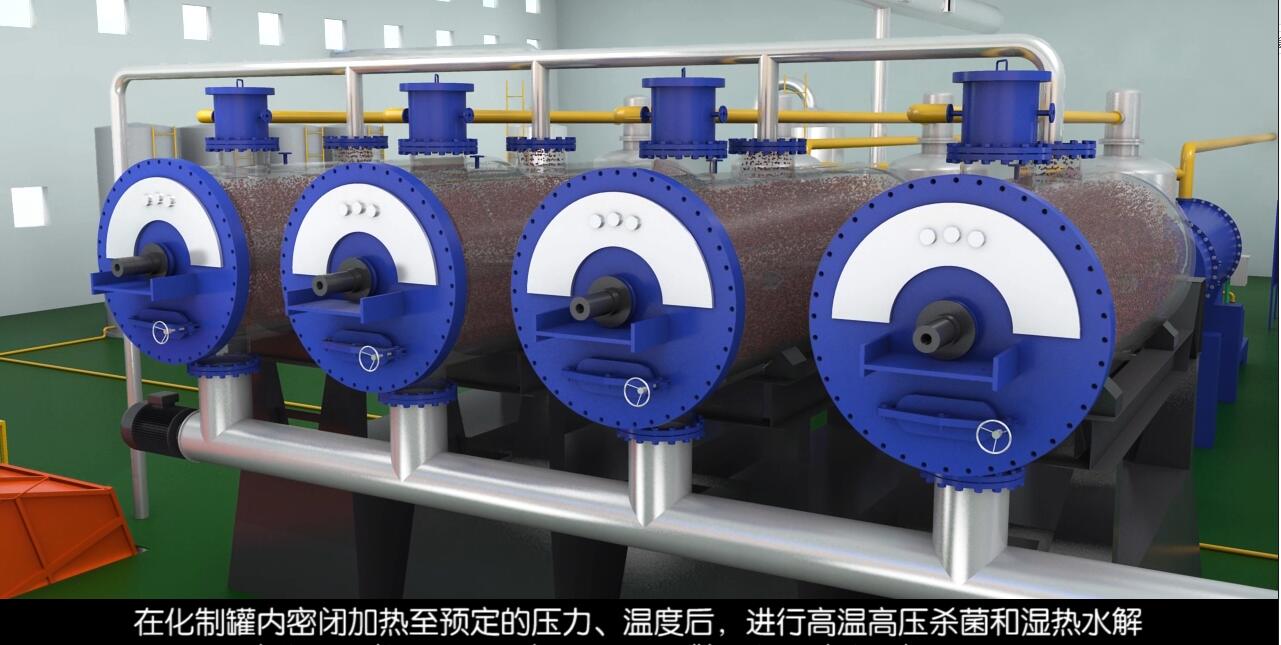

5, chemical drying: After the temperature and pressure in the tank reach the preset value, keep it for 30 minutes (the pressure and temperature can also be adjusted according to different materials), and then empty and relieve pressure to enter the drying stage. After drying for 2 hours by low temperature vacuum drying (adjustable), the water content of the material is reduced to 10-12% and the material containing about 30% grease.

6, discharge: the completed material through the screw conveyor to the storage warehouse temporary storage.

7, press degreasing: the material of the storage bin is transported to the screw press by screw conveyor for degreasing oil, and the oil residue is separated to obtain meat bone slag and animal fat.

8, cooling and crushing: meat bone residue after degreased oil to form shingle material, and then by the air cooling system after treatment to drop to room temperature, and then crushed is one of the finished products of the treatment - finished meat and bone meal, and then by the automatic packaging machine packaging, packaging into the warehouse for sale.

9, oil purification and storage: the animal fat obtained by the oil press, heated by the heating tank, through the horizontal centrifuge purification, that is, after the completion of the treatment of another product - industrial animal fat, pumped into the oil storage tank.

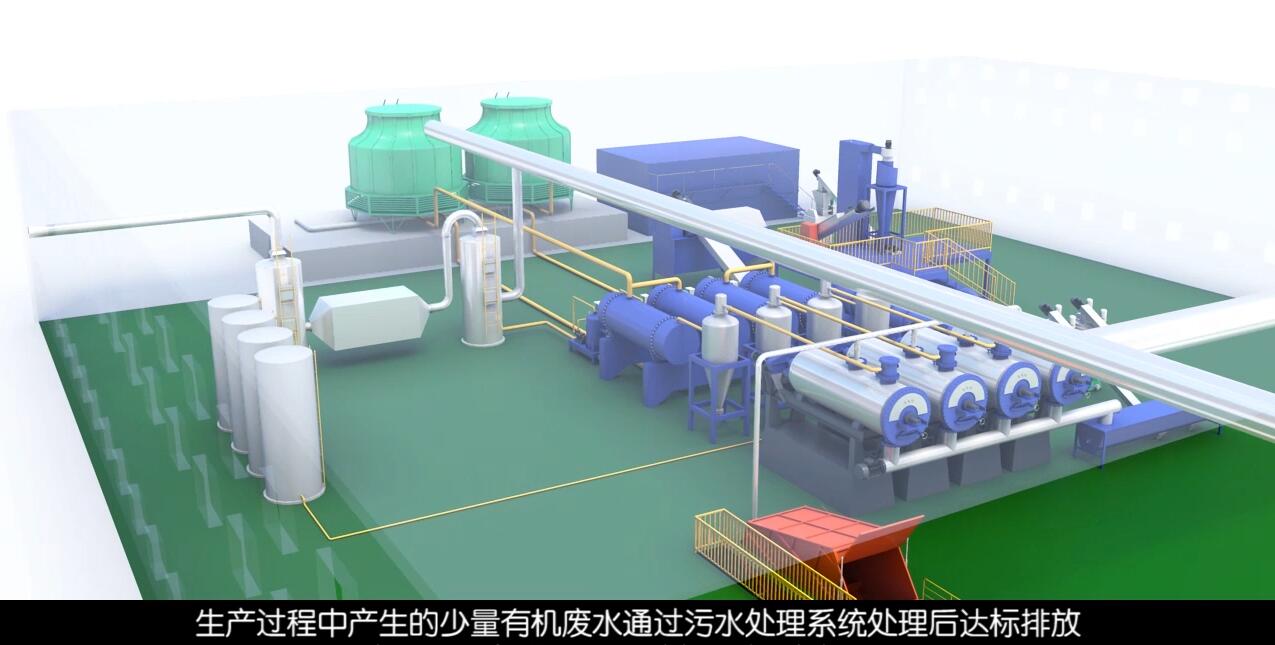

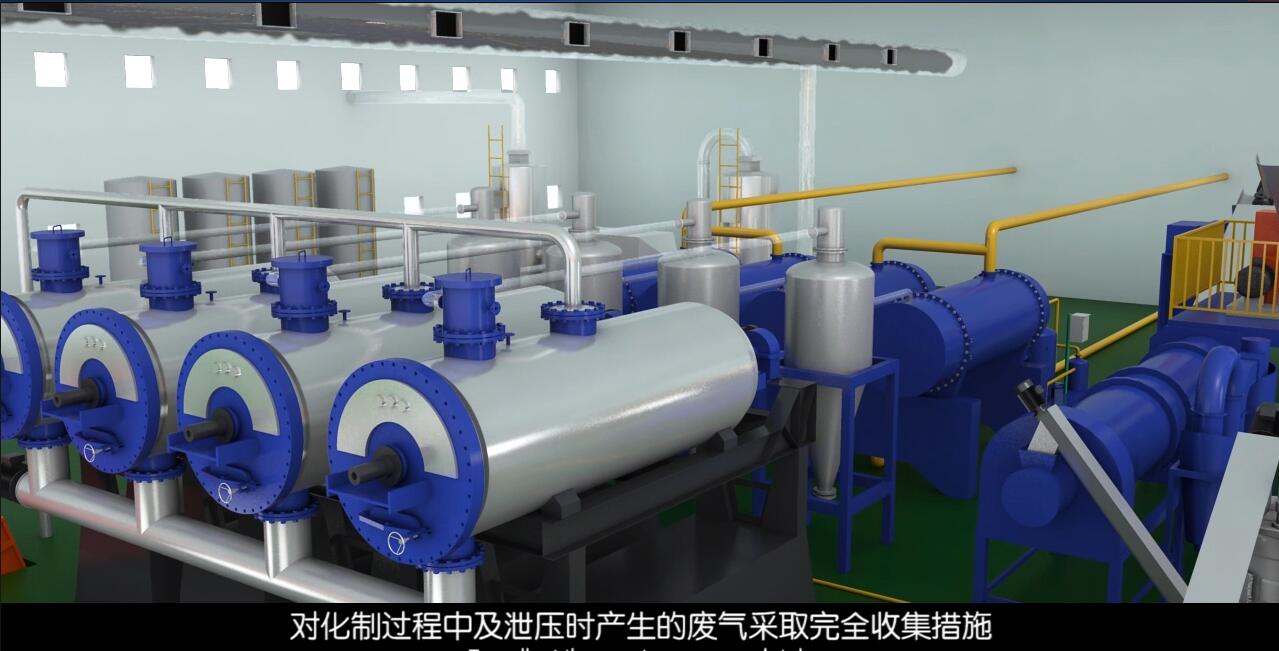

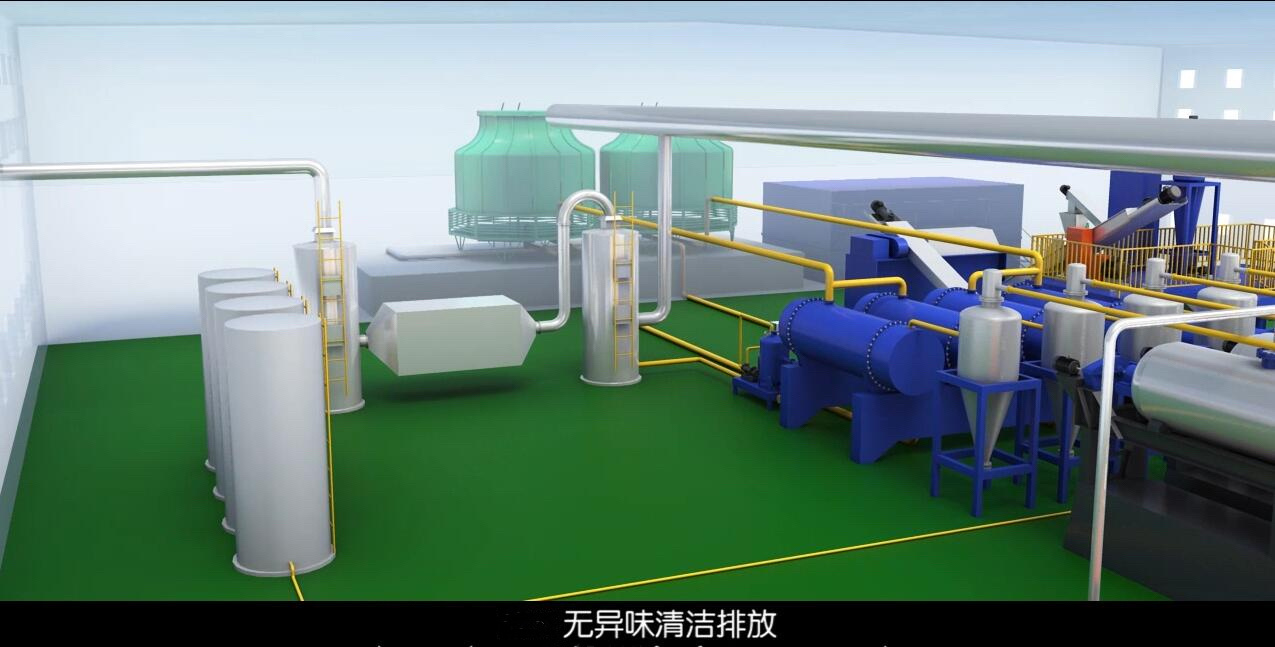

10, exhaust gas treatment: in the drying process, the exhaust gas generated by the dust collector dust, into the spray tower spray agent washing, and then by photonic catalytic oxidation (optional) treatment into the biological filter, deodorization.

11, condensate primary treatment: a small amount of condensate generated in the drying process, after adding flocculant precipitation, multistage filtration, adding deodorant, as irrigation water discharge.